Replacing the Steering Stem Bearings

- Here is a link to a video showing what bad stem bearings are like:

http://www.youtube.com/watch?feature=player_embedded&v=VBO0SiRBT6E

- Here is a post from 2010 on replacing the steering stem bearings and some of the problems encountered.

I just replaced my ball bearings for tapered in my GL650 today. I chose Pyramid brand off the bay for the bearings. As I was reading up on the subject last night on the Oz website, there was a reference to installing a washer between the lower thin washer and the rubber dust seal. I didn't really follow why this was needed until the bearings came today. The old ball bearing races have a lip that fits inside the dust ring to space the dust ring away from the bearing. The tapered ones do not have this lip, and need a washer to space the inner race away from and centered on the dust seal. If you don't have this spacer, the dust seal will be compressed against the bearing and cause binding

The Oz guys were making their own from tubing and a lathe. Well, I didn't have the right size tubing and sold my lathe 10 years ago. So after looking thru all my parts bins and not finding the right size washer, I decided to make my own. This washer/spacer needs to be a snug fit over the bearing shaft, and a snug fit inside the dust seal. It also needs to be the thickness of the dust seal, or maybe a tad less.

I took a piece of #8 solid ground copper wire and bent it around a appropriate size socket, then cut the ring off on a diagonal and silver soldered the ends together. After a bit of tweaking with a Dremel on the ID and OD it fit perfect. The thickness was a bit too much, so I sanded the top and bottom on a flat bed sander. Now everything looked good.

I reassembled the triple tree and all seems fine. No binding and was able to go a bit past finger tight on the adjuster. I'm not sure why Pyramid doesn't include this in their package, but they do not. I'm not sure of All Balls product. So if you don't get this spacer when converting, count on making one. I doubt that you could find the right size in a hardware store.

Here is the discussion of the problem from the Australian CX site

Hey All,

Have just received new taper roller bearings through the post (thanks Joe Hovel), and am just wondering if anyone has any diagrams on how it all goes together, as the book isn't that clear. Have got the races seated into the fork tube no problems with a mallet, hammer and alloy drift, but have read on various posts on here about a lower sealing washer? All I seem to have is a very thin washer that goes under the lower bearing on the triple tree (is that correct term). I take it the lower roller bearing just sits straight on this as there is no need for seperate outer races. Any advice would be appreciated.

Clarky.

| « Last Edit: February 21, 2009, 06:03:55 PM by Clarky » |

Clarky, see if you can find a thick thin-walled washer or very short piece of tubing about the size of the ridge on the old bearing that the seal used to sit on. Then fit that between the bottom triple clamp and the washer, with the bottom seal fitted to that. Then put the bottom bearing on top of tha and reassemble. That's what iI did on one occasion.

Thanks for the quick reply Joe - Think I understand. That lower washer was just a seal retainer then, and that washer you're talking about is just to sandwich the dust seal correctly - to do the job that the outer race used to do?

- Attached files'Thumbnail(s):

- Thumbnail(s):

File:Washer File:Washer File:Washer File:DSCF1262 File:DSCF1271 File:DSCF1272 File:DSCF1273 File:DSCF1274 File:DSCF1275 File:DSCF1276

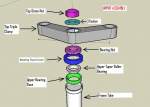

Have finally got around to drawing up the whole bearing assembly including frame fork tube (attached).

- Attached files'Thumbnail(s):

File:Front File:Front  Thanks to Clarky for the drawings and photos.

Thanks to Clarky for the drawings and photos.

I have also used a "All Balls" steering bearing kit to replace the original ball bearings that Honda supplied. It did come with the spacer washer that is required to hold the new roller bearing away from the dust seal. In fact, they send two of different thicknesses to let you choose from. At least the directions sorta tell you which one you should use. Just follow the directions and think about it for a bit and you will be OK.

Getting the old races out seem to be a challenge for some people. I used a short section of EMT electrical conduit that would fit thru the stem opening to rest on the race. Then a couple of taps to different sides and the races popped out. Getting the race off the bottom of the triple tree stem can seem daunting, as the the dust seat and a washer makes access only available only at a angle. But with a long metal punch, you can rest it at a angle on the race and by tapping and moving around, the race will start moving quickly. A good vise is almost necessary for lots of bike service, I would recommend getting a good one, and mount it securely. Get a 5" wide jaw with a 6" opening if possible. I would buy used, vises seldom wear out and a new good one can run several hundred dollars.

Here is a post from Coffee Brake on how she adjusts the tightness of the new bearings:

Well the way I've seen it (and other more experienced folks may say different), wheel bearings may last 100k miles, or they may go out at about 35k. Truthfully, I've only had one set legitimately fail, and the rest I've changed preemptively.

Neck bearings, however, tend to go bad with time AND/OR miles. Even sitting on the showroom floor, neck bearings go bad after years and years of holding up the bike. Neck bearings also require adjustment more frequently than you would imagine, but they rarely get it so they go bad faster than they should. You'll find the new tapered bearings a big improvement over the stock ball bearings. But plan on going back in there at least once and likely 3-4 times in the first two thousand miles to adjust the new bearings. All you do is pull the top triple and tighten the nut just so.

Most folks don't get it tight enough, and the bearing works loose far too soon. Here's how tight I get it: I tighten that nut under the triple so tight that I have to push on the tire to get the front wheel to move side to side. Not a little nudge, but not a huge force either. Think of the force it takes to push, say, a toaster across the kitchen counter. That much force. Then I back it out just 1/8 turn, because putting the nut on TOP of the triple is going to tighten it a bit.

The forks should move smoothly to their stops, but they should not bounce off the stops. The manuals say to measure the bounce or some such nonsense, but IMO that's not tight enough. Catchy, grabby motion is too tight and will ruin your new bearings and seats. But bouncing off the stops is too loose and within 15 miles you're going to be doing damage to sloppy bearings.

If that doesn't make sense, I'll be glad to talk you through it. Augusta, GA 1979 CX500 Custom 2005 Concours ZG1000 1999 Bandit 1200 1986 VFR700

And here is a link to a 2008 forum discussion on the same topic:

http://choppercharles.com/cs/forums/26029/ShowPost.aspx

Another link to the forum on head tube bearing replacement. http://cx500forum.com/index.php?/topic/21007-oh-its-on-headless-rufus/pagep235488#entry235488

Another great write up on replacing head tube bearings by Reg in Bristol http://cx500forum.com/index.php?/user/128-reg-in-bristol/pagef5 . [viewfindpostp269710|Link to CX/GL forum]

Its been few years since I fitted tapers to my 79 frame but just had a look at it and I have the thick washer on the bottom of the stem for the lower race to sit on Changing the top race out is easy but the lower needs a bit of forethought and malice. You need a long drift with enough of an edge to catch the small overhang of the old race and try not to score the tube it sits in while driving it out.

When I got the tube clear I saw the bottom race was somewhwt deeply recessed and while it has to be snug fit and not turn in it socket, it doesn't have to be 'murder tight' as my old apprentice master use to say so I cleaned and polished the lower,inner headstock tube gently with a dremel and fine wheel. the new taper race went in snugly with moderate tapping not mad hammering and bearing faces were undamaged.

After fitting the washer on the spindle, the new inner race has to be driven down the shaft to sit on it snug and square I checked for any scoring crap or damage and did a light polish and was careful I only tapped down on the inner part not the outer rollers A stout steel tube just wider than the spindle is very nice for this job if you can get one otherwise be careful not to clout the rollers

Once you have the old races out, cleaned things up and fitted the new lower taper to the spindle, its plain sailing. Lotsa fresh clean grease obviously I tend to over tighten them slightly at first to bed the outer races then slacken them off for a first fit. You may want to Dremel off the wee nubs on the lower side of the top cap to get a face to face fit where it holds down the race.

Also soon after riding it will probably settle, slacken and need readjusting again and tightening up a bit. Once I did that I found I didn't need to touch it for ages. HTH

This site is backed by Number 85, who provide the hosting. If you need a website done, get in touch with them.